The popularization rate of automation equipment in enterprises is getting higher and higher. At the same time, the failure rate of automation equipment is also rising. Any automation equipment is composed of executive components, sensors and controllers. When the automation equipment suddenly fails to work, or due to the order of work, the equipment is out of order, we must carry out troubleshooting and fault diagnosis.

In order not to affect the normal work of automation equipment, daily diagnosis mainly includes the following five aspects:

one

Check all power, origin, hydraulic sources of automation equipment

Problems with power, origin and hydraulic sources often lead to failure of automation equipment.

For example: there is a problem with power supply, including the failure of power supply in the whole workshop. Or the power supply is low, the fuse is burned, the power plug is in bad contact, etc. The power supply of each equipment and power supply of workshop shall be included in the detection of automation equipment. Air source, including air pressure source required by pneumatic device. Hydraulic source, including the operation of hydraulic pump required by hydraulic device of automatic equipment.

two

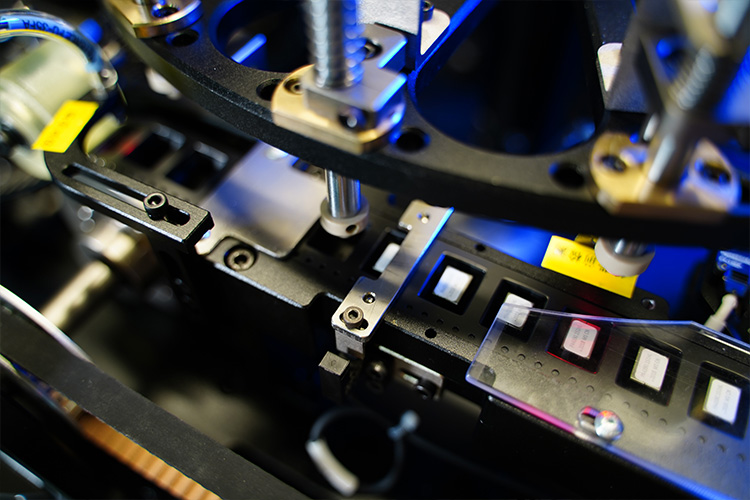

Check for offset of sensor position of automation equipment

Some sensors may be located incorrectly due to the negligence of the maintenance personnel of the equipment maintenance personnel. For example, it is not in place, the sensor is faulty, etc. Technicians should check the sensor position and sensitivity frequently. If it is found that the sensor is damaged, it should be replaced in time.

Sometimes, due to the vibration relationship of automation equipment, most sensors will loose after long-term use. Therefore, it is necessary to check whether the position of sensors is correct, whether they are fixed and firm during daily maintenance.

three

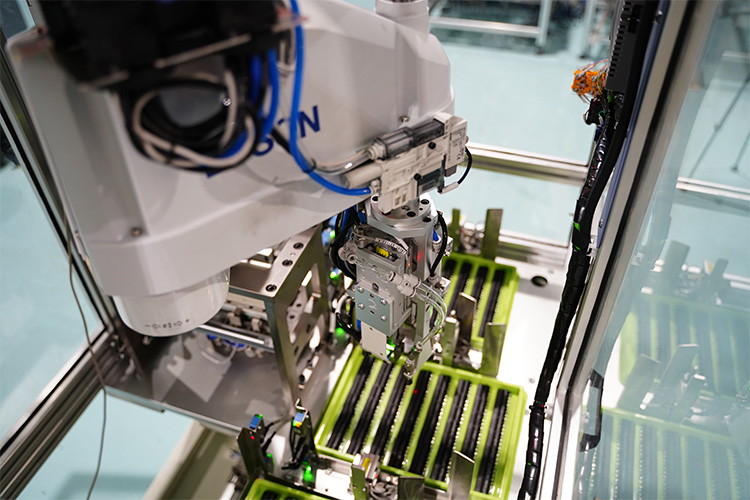

Check the relay, flow control valve and pressure control valve of automation equipment

Relay and magnetic induction sensor, long-term use will also appear iron adhesion, which can not guarantee the normal electrical circuit, need to be replaced. In the pneumatic or hydraulic system, the opening of throttle valve and the pressure regulating spring of pressure valve will also loosen and slide with the vibration of the equipment. In fact, these equipment and sensors are the same, in the automation equipment need routine maintenance parts.

four

Check the electrical, pneumatic and hydraulic circuit connections

If no problem is found in the above three steps, check all circuits. Check whether there is a short circuit in the circuit wire, and check whether the wire in the trunking is cut by the trunking due to pulling. Check the trachea for damaging creases. Check the hydraulic oil pipe for blockage. If there is a serious crease in the trachea, the technician needs to replace it immediately. The hydraulic oil pipe should be replaced at the same time.

five

If there is no problem in the above steps, the fault may appear in the controller of automation equipment, but it can never be a program problem. When the equipment fails, the technicians should not immediately confirm that the controller is damaged, because there is no serious short circuit. The controller has short circuit protection inside, and the controller will not be burned in general short circuit.