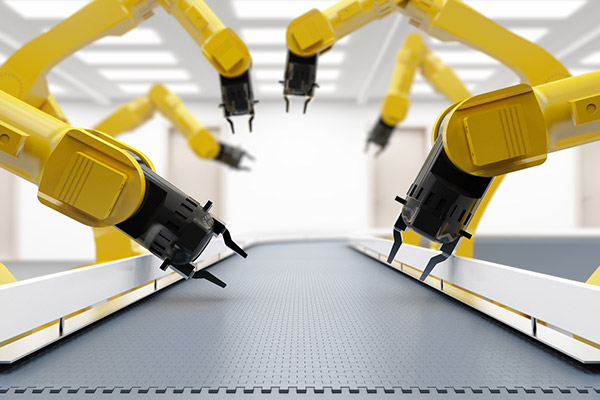

With the proposal and deepening of 'industry 4.0' and 'made in China 2025', the global manufacturing industry is developing towards automation, integration, intelligence and green. As the largest manufacturing country in the world, intelligent manufacturing marked by industrial robots is more and more widely used in various industries in China.

1、 Metal forming

Metal forming machine tool is an important part of machine tools. Forming process is usually associated with high labor intensity, noise pollution, metal dust, etc. sometimes in high temperature, high humidity and even polluted environment, the work is simple and boring, and it is difficult for enterprises to recruit people. The integration of industrial robot and forming machine tool can not only solve the problem of enterprise employment, but also improve the processing efficiency, accuracy and safety, and has a great development space.

Industrial robots in metal forming field mainly include numerical control bending machine integration application, press press stamping integrated application, hot die forging integrated application, welding application and so on.

2、 Electronic and electrical

Industrial robots are also widely used in electronic IC and patch components. At present, the most installed industrial robot in the world is SCARA type four axis robot. The second is series joint 6-axis robots, which exceed half of the global industrial robots.

In the field of electronic and electrical, industrial robots have performed well in a series of processes, such as sorting and packing, tearing film system, laser plastic welding, high-speed stacking, etc.

3、 Plastics industry

From the automotive and electronic industries to consumer goods and food industries, plastic is in the figure. Plastic raw materials are processed into fine and durable finished products or semi-finished products through injection molding machines and tools. This process is often indispensable for industrial robots.

Industrial robot is not only suitable for the operation under the environmental standards of clean room, but also can finish high-strength operation beside the injection molding machine, and improve the economic benefits of various processes. The advantages of industrial robot are fast, efficient, flexible, durable and strong bearing capacity, so as to ensure the competitive advantage of plastic enterprises in the market.

4、 Foundry industry

The foundry industry is heavily burdened by workers and machines because they need to work in multiple shifts in extreme working environments such as high pollution, high temperature, gravity, etc. Therefore, more and more enterprises pay attention to and implement green casting.

The foundry industry extends from pouring and handling to cleaning and stacking. Industrial robots can be used to improve the working environment, improve the work efficiency, product precision and quality, reduce costs and reduce waste, and obtain flexible and high-speed and durable production process, which can meet the special requirements of green casting.

5、 Household appliances industry

Household appliances have always been labor-intensive industries. Under the promotion of the objective factors such as the substantial increase of human cost, the gradual disappearance of China's population dividend and the improvement of precision manufacturing, the application of industrial robots in the field of household appliances is inevitable.

Industrial robots can be used to complete production, processing, handling, measurement and inspection more economically and effectively, and can complete production tasks continuously and reliably without frequent transfer of heavy parts. Thus, the material flow of production line can be ensured smoothly and the constant and high quality can be maintained.

6、 Food industry

Food products tend to be refined and diversified, and the products of large quantities of single varieties are less and less, while many kinds of small batch products are becoming the mainstream. Most of the packaging work in domestic food factories, especially the arrangement and assembly of more complex packaging items, is basically manual operation, which is difficult to ensure the unity and stability of packaging, which may cause pollution to the packaged products. The application of robot can effectively avoid these problems. By integrating sensor technology, artificial intelligence and robot manufacturing, the robot system can automatically adapt to the changes in product processing and realize intelligent control.

The application of industrial robots in food mainly focuses on several types: packaging robot, picking robot, stacking robot and processing robot. At present, food industry robots have been developed, including canned packaging robot, automatic lunch robot and beef cutting robot.

7、 Metallurgical Industry

Whether it is light metal, color metal, precious metal, special metal or steel, the metal industry cannot be separated from foundry and steel / metal processing. Moreover, without automation and multi shift operation, it is impossible to ensure the economic benefits and competitiveness of production and reduce the heavy work of employees.

The main work scope of industrial robot in metallurgical industry includes drilling, milling or cutting, bending and stamping. In addition, it can shorten the working cycle of welding, installation and loading and unloading process and improve productivity.

8、 Chemical industry

Chemical industry is one of the main application fields of industrial robots. Facing the requirements of precision, high purity, high quality and miniaturization of modern chemical products, the production environment requires a clean environment, and the clean technology directly affects the qualification rate of the products. Therefore, in the field of chemical industry, with the increasing requirements for environmental cleanliness in more and more chemical production occasions in the future, clean robots will be further used, so it has a wide market space.

9、 Tobacco industry

In tobacco industry, such as the distribution of cigarette raw materials and auxiliary materials, advanced automatic logistics system is needed to complete. Traditional manual management, manual handling is easy to make mistakes and is not timely, which can not meet the needs of production development. The paper uses industrial robot to stack the finished cigarette products, and AGV (self-propelled trolley) is used to carry the finished product tray, which saves a lot of manpower, reduces the damage of the cigarette box and improves the automation level.

10、 Glass industry

Whether it is hollow glass, flat glass, tubular glass or glass fiber, modern and mineral containing high-tech materials are very important parts of the electronic and communication, chemical, pharmaceutical and cosmetic industries. And now it's indispensable for the construction industry and other industrial branches. Especially for glass with high cleanliness requirements, industrial robots are the best choice.

The industry robot field needs a lot of capital and technology investment, and the perfect industrial ecological layout to support, in order to achieve good development. Chengdu guoruntong Technology Development Co., Ltd. has built one-stop integrated service platform for industrial robots, providing customized automation solutions for customers, and is committed to becoming the world's leading service provider of the whole industry chain of intelligent equipment. We hope that the industrial robot industry chain in China can have independent strategy in the future, and can keep the innovation consciousness at all times, and seize the opportunity to realize the overtaking of the curve.